The P0036 code indicates an issue with the heater control circuit for the oxygen sensor located after the catalytic converter on Bank 1 (Sensor 2). This heater is essential for getting the sensor to its operating temperature quickly, which helps in managing fuel efficiency and emissions.

P0036 quick overview

| Meaning | P0036: HO2S Heater Control Circuit – Bank 1 Sensor 2 |

| Is it serious? | This code is not critical but should be addressed to ensure optimal engine performance and fuel efficiency. |

| Possible causes | -Corroded or missing exhaust ground -Faulty wiring to the oxygen sensor (HO2S) -Blown fuse for the O2 sensor -Faulty HO2S sensor (Bank 1 Sensor 2) -Faulty PCM (very rare) |

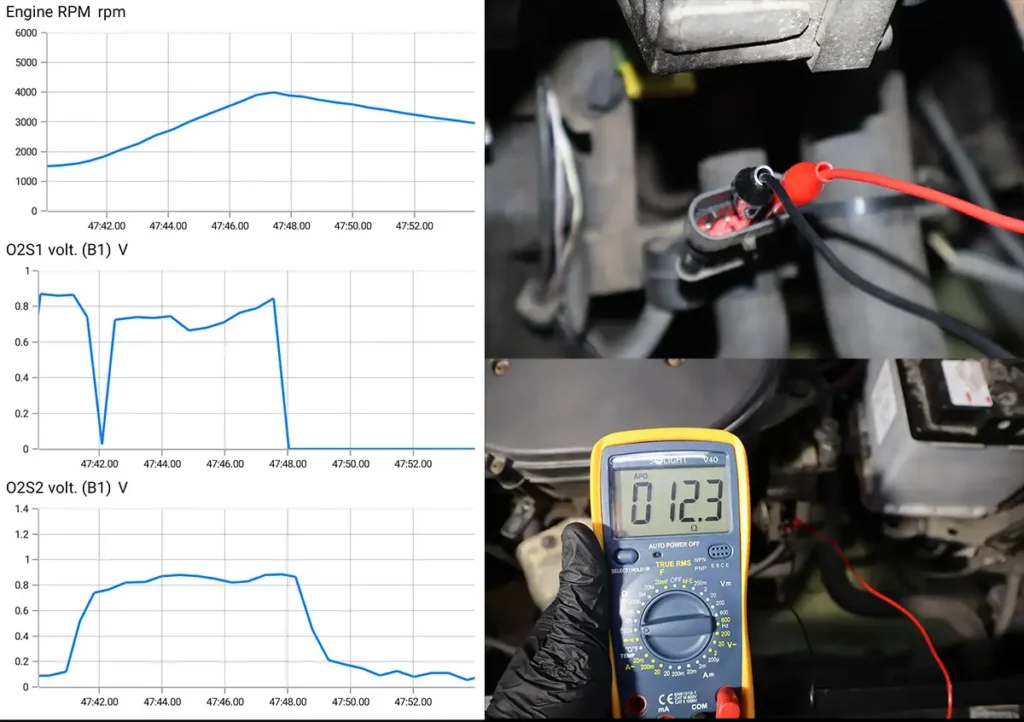

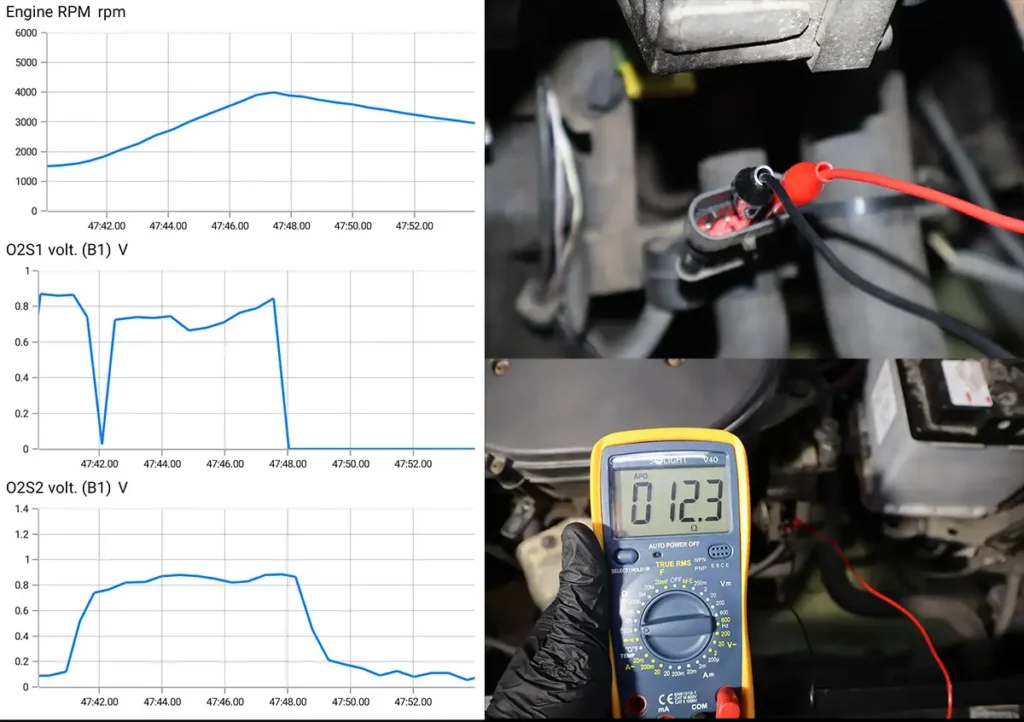

| How to diagnose? | Erase the Code: Connect an OBD2 scanner to the car and erase the fault codes. See if the code reappears after driving. Check Exhaust Ground: Inspect the exhaust ground cable for corrosion or damage and ensure it is properly connected. Inspect Wiring: Check the O2 sensor’s wiring for damage, wear, or disconnection, especially around the connector. Test Fuses: Locate and test the fuses related to the O2 sensor using a digital multimeter or replace them with new ones to rule out a blown fuse. Replace the O2 Sensor: If the wiring and fuses are intact, replace the oxygen sensor with a new, preferably OEM sensor. |

Test oxygen sensor PDF

- How to locate a specific sensor (bank1, 2)

- How to test with a multimeter

- How to test using an OBD-II reader

- Verify O2 sensor/CAT just with live data

Case Study: How to fix P0036

I looked into 10 different cases of solving this problem on different cars. This is what I’ve learned by analyzing all cases:

common fixes

| Fix | Percentage |

|---|---|

| Replacing O2 sensor (OEM part) | 50% |

| Repairing wiring or corroded connectors | 30% |

| Inspecting and fixing powertrain relays | 10% |

| Other (fuses, ground connections, PCM repair) | 10% |

common mistakes:

- Using aftermarket O2 sensors that are incompatible with the system, causes recurring codes.

- Ignoring wiring issues like corrosion, poor connections, or damaged harnesses, especially in areas prone to wear.

- Failing to load-test the circuits to ensure they can carry current, leads to missed wiring faults.

- Overlooking the importance of properly seating connectors, particularly in underhood electrical components.

- Not resetting or relearning the O2 sensor heater circuit using a scan tool, resulted in codes coming back.

key takeaway:

- Always use OEM O2 sensors to avoid compatibility issues.

- Thoroughly inspect the wiring for corrosion or breaks, especially in areas exposed to the elements.

- Perform load tests on wiring circuits to detect current flow issues rather than relying solely on visual inspections or resistance checks.

- Check power and ground connections, especially at fuse boxes and relays.

Case #1: Toyota

Vehicle information: 2003 Toyota Sienna CE 3.0L

Issue + repair history: The vehicle had the MIL lamp on with code P0036. The technician was unsure of the exact definition of the code and asked for assistance. The spark plugs, A/F sensor (Bank 1 Sensor 1), and valve cover gasket were previously replaced.

Other codes + test results: None reported

Other mechanics suggestions:

- P0036 refers to the oxygen sensor heater circuit for Bank 1, Sensor 2 (downstream O2 sensor).

- Several suggestions advised replacing the O2 sensor with a Denso OEM part to avoid compatibility issues.

- The sensor plug is located under the passenger seat; the trim and carpet need to be removed for easy access.

- Some mechanics suggested verifying the heater circuit for opens or shorts by checking resistance across the heater element (which should be 11-16 ohms).

Final fix: The rear O2 sensor was replaced with a Denso part, which resolved the issue.

Case #2: Chevrolet

Vehicle information: 2008 Chevrolet Silverado 1500 LT 5.3L

Issue + repair history: The vehicle came in with multiple O2 heater circuit codes for Bank 1, Sensor 2, along with a P0300 engine misfire code. Although the misfire could not be duplicated, the technician replaced the B1 S2 O2 sensor and cleared the codes. After the truck sat for three hours, the same codes (P0036 and P0141) returned. The technician sought advice before proceeding with deeper wiring or PCM diagnostics.

Other codes + test results:

- P0036 – O2 heater circuit (Bank 1, Sensor 2)

- P0141 – O2 sensor heater circuit malfunction (Bank 1, Sensor 2)

- P0054 – O2 heater resistance (Bank 1, Sensor 2)

- P0138 – O2 sensor circuit high voltage

- P0300 – Engine misfire

- P2270 – O2 sensor signal stuck lean

Other mechanics suggestions:

- Check the fuse for the O2 heater circuit.

- Perform a current load test on the wiring using a halogen bulb to ensure the wires can carry current properly.

- Inspect the wiring harness under the vehicle, especially near the driveshaft, which may rub against the harness and cause short circuits.

- Check the low reference circuit from the ECM for pulse width modulation control of the heater circuit before condemning the ECM.

- Always use OEM O2 sensors.

- Verify that the O2 heater relearn procedure was completed using a scan tool.

Final fix: The issue was traced to a corroded spot in the O2 sensor heater voltage supply wire, located where the harness loops over the frame near the transmission. After repairing the wire, the O2 heater circuit functioned correctly, and the codes did not return.

Case #3: Hummer

Vehicle information: 2006 Hummer H3 3.5L

Issue + repair history: The vehicle came in for a water pump replacement, but the customer reported reduced power, poor idle quality, and a maximum speed of 40 mph. When the vehicle arrived, it initially ran well, but multiple codes (P0030, P0036, P2101) were stored. Current codes included P0135, P0141, P0300, P1516, and P1682. The technician suspected an issue with the powertrain relay, wiring, or PCM, but the issue only occurred intermittently. The O2 heater and PCM power circuits were checked, and wiring and connectors were inspected without finding obvious issues.

Other codes + test results:

- P0030 – O2 heater control Bank 1 Sensor 1

- P0036 – O2 heater control Bank 1 Sensor 2

- P0135 – O2 heater performance Bank 1 Sensor 1

- P0141 – O2 heater performance Bank 1 Sensor 2

- P2101 – Throttle actuator position performance

- P1516 – Throttle actuator control module

- P1682 – Ignition 1 switch circuit 2

- P0300 – Engine misfire detected

Other mechanics suggestions:

- Inspect powertrain relay operation, particularly fuses #46 and #47 for the O2 sensors and throttle actuator circuits.

- Reseat connectors in the underhood electrical center, as loose connections can cause intermittent power to the O2 sensors and throttle actuator.

- Check the throttle body to throttle actuator harness for poor connections, especially where the harness might have been previously spliced.

- Perform voltage drop tests to verify power and ground to the TAC module and ECM.

Final fix: The issue was traced to improperly seated connectors in the underhood fuse box. One of the connector latches was wedged inside the connector, preventing proper contact. After reseating the connectors and reassembling the fuse box correctly, the problem was resolved. The vehicle ran smoothly, and the codes did not return after 16 days.

Case #4: Chevrolet

Vehicle information: 2006 Chevrolet Equinox LS 3.4L

Issue + repair history: The vehicle came in with poor idle quality, hesitation, intermittent stalling, and non-operational cooling fans. The check A/C issue was reported as not cooling at idle but functioning fine while driving. Although the overheating issue was not initially reported, it was discovered during diagnostics. The vehicle had numerous codes related to O2 sensors, injectors, fuel pump relay, and EVAP system issues.

Other codes + test results:

- P0030 – HO2S Heater Control Circuit (Bank 1 Sensor 1)

- P0036 – HO2S Heater Control Circuit (Bank 1 Sensor 2)

- P0201 – Injector 1 Control Circuit

- P0206 – Injector 6 Control Circuit

- P0230 – Fuel Pump Relay Control Circuit

- P0442 – EVAP System Small Leak Detected

- P0443 – EVAP Purge Solenoid Control Circuit

- P0449 – EVAP Vent Solenoid Control Circuit

- Several other codes

Other mechanics suggestions:

- Inspect the cooling fan system, as proper cooling is required to keep the A/C system within range. The high side pressure rises and falls with temperature changes.

- Check the instrument panel/body inline connector (black 40-pin connector) for bent or corroded terminals, which can cause intermittent issues and numerous codes.

- Inspect for poor connections at the PCM harness connectors, as many codes, including the EVAP-related ones, can be caused by a bad PCM connection or a faulty PCM.

Final fix: The issue was traced to condensation and poor terminal connections in the PCM connector. After cleaning and reassembling the PCM connector, the vehicle’s problems were resolved. The cooling fans, idle quality, and stalling issues were all corrected, and the codes did not return.

Case #5: Chevrolet

Vehicle information: 2010 Chevrolet Traverse LT 3.6L

Issue + repair history: The vehicle had poor idle quality, frequent stalling, and misfires, particularly on Bank 2. The throttle had no response, and the short-term fuel trim (STFT) for Bank 2 was maxed at 25%, while Bank 1 was within normal range. Additionally, there were no O2 sensor readings for Bank 2, and the load was at 99%, causing the vehicle to stall after idling for 10 minutes. The Accelerator Pedal Position (APP) % was erratic, and the technician found no data for the camshaft position (CMP) sensor. The throttle body (TB) and MAF sensor were previously cleaned.

Other codes + test results:

- P0336 – Crankshaft position (CKP) sensor performance

- P0102 – Low MAF frequency

- P0036 – O2 heater low voltage Bank 1 Sensor 2

- P0300 – Random misfire

- P0335 – Crankshaft position sensor circuit malfunction

- P0302, P0304, P0306 – Misfire on cylinders #2, #4, and #6

Other mechanics suggestions:

- Check for a clogged catalytic converter on Bank 2, which can cause misfires and poor performance.

- Test for excessive back pressure or drop the exhaust to see if performance improves.

- Inspect for timing chain issues, as worn guides or a jumped chain can affect cam timing and fuel trims.

- Check the ignition coils and fuses, as a faulty coil or popped fuse can cause issues on one bank.

- Perform a relative cranking compression test to verify if compression is lower on Bank 2.

Final fix: The catalytic converter on Bank 2 was clogged, causing misfires and stalling. The vehicle was sent to an exhaust shop for repairs, and replacing the catalytic converter resolved the issue.

Case #6: Pontiac

Vehicle information: 2006 Pontiac G6 3.5L

Issue + repair history: The vehicle experienced poor idle quality, hesitation, stalling, and no throttle input. The car would sometimes redline RPMs after starting, idle down, or start and die immediately. The display showed “ENG PWR Reduced,” and the car accelerated without throttle input, reaching speeds of 60 mph. The customer mentioned clearing the codes helped temporarily in the past, but the problem returned. The technician retrieved various codes, including throttle control and O2 heater circuit issues, and performed an initial visual inspection without finding any obvious problems.

Other codes + test results:

- P0030 – HO2S Heater Circuit (Bank 1 Sensor 1)

- P0036 – HO2S Heater Circuit (Bank 1 Sensor 2)

- P0050 – HO2S Heater Circuit (Bank 2 Sensor 1)

- P0056 – HO2S Heater Circuit (Bank 2 Sensor 2)

- P0068 – MAF/MAP Sensor Throttle Position Correlation

- P0102 – MAF Circuit Low

- U0107 – Lost Communication with Throttle Control Module

Other mechanics suggestions:

- Check the powertrain relay (Relay 33) as it powers the heater circuits and the throttle actuator control module.

- Inspect the fuse circuits (ETC Fuse 2 and Emission 1 Fuse 6) for proper voltage, as they are powered by Relay 33.

- Look for any loose or damaged connectors at the PCM, as bad connections can cause lost communication with the throttle control module.

Final fix: The issue was traced to a misaligned weather seal and a plastic piece blocking proper connection at PCM connector C1. After removing the obstruction, reseating the connector, and testing the circuit (5069), the PCM was able to energize the relay correctly. The codes were cleared, and the vehicle ran smoothly. A road test confirmed no further problems.

Case #7: Kia

Vehicle information: 2005 Kia Rio 1.6L

Issue + repair history: The vehicle had a poor fuel economy issue, and the MIL was illuminated. The O2 sensors were replaced multiple times, including replacing them with OEM parts. Despite following diagnostic procedures from All-Data and Mitchell, the problem persisted. The computer (ECM) was also replaced, but the code P0036 reoccurred. Testing showed the heater supply wires only had 4.5 volts, lower than the expected B+ voltage, and there was no open or short in the circuit.

Other codes + test results:

- P0036 – O2 sensor heater circuit (Bank 1, Sensor 2)

- P0030 – Upstream O2 heater malfunction

- P0420 – Catalyst efficiency below threshold (Bank 1)

Other mechanics suggestions:

- Test the heater operation of O2 sensors.

- Verify if the connectors were switched between the upstream and downstream O2 sensors.

- Check if the power supply to the O2 sensors is consistent with key on and inspect the wiring for voltage drop.

- Perform a vacuum gauge test to check for a clogged catalytic converter and graph the O2 sensors to compare pre- and post-cat readings.

- Visit the Kia technical information website to follow factory diagnostics, as it offers more precise guidance compared to other resources.

Final fix: After extensive testing and finding no opens or shorts in the wiring, the ECM was found to be supplying an incorrect voltage (4.39 volts instead of zero). The case was unresolved, as the vehicle was sent to the Kia dealership for further diagnostics due to the complexity of the issue and the time spent on it.

Case #8: Toyota

Vehicle information: 2003 Toyota Avalon XL 3.0L

Issue + repair history: The customer reported that the vehicle died while driving, with no prior warning, and the check engine light came on. The vehicle stored a P0036 code for the O2 sensor heater control circuit (Bank 1, Sensor 2). The technician checked for spark and fuel delivery and found both to be functioning. However, the engine took much longer than normal cranking time to reach the specified compression. Timing marks appeared to be aligned, and everything was turning as expected during cranking.

Other codes + test results:

- P0036 – Oxygen sensor heater control circuit (Bank 1 Sensor 2)

- Spark: Present

- Fuel: Present, injectors delivering fuel

- Compression: Took longer to reach normal compression in the front cylinders.

Other mechanics suggestions:

- The timing belt may have jumped time. Check alignment closely, do a leak-down test on cylinder #1.

- Open the radiator cap during cranking to see if coolant is being pushed out, indicating a possible head gasket issue.

- Try starting the vehicle with the throttle fully open, as a stuck idle air control (IAC) valve could restrict breathing and lead to poor compression readings.

- Check for a sheared keyway in the timing gear on the crankshaft, which could make the marks line up but still cause incorrect timing.

- Consider that the timing belt may have stripped teeth, which could affect tension and alignment, causing timing problems.

Final fix: The problem was caused by a faulty water pump bearing, which led to the timing belt shredding on the inside edge. This was not visible from the top side of the engine. Fibers from the belt wrapped around the crank pulley, causing timing issues. After replacing the water pump and timing belt, the vehicle ran perfectly.

Case #9: Mini

Vehicle information: 2002 Mini Cooper 1.6L

Issue + repair history:

The vehicle, purchased as a project car, originally did not run. The customer repaired the MAP sensor harness and got the engine running, but it entered Limp-In Mode above 2000 RPM. Initially, the DME (Digital Motor Electronics) had codes P0036, P0130, and P0340. The technician focused on the P0340 code (Camshaft Sensor), replaced the sensor, and the code did not return. However, the vehicle still entered Limp-In Mode, with throttle angle locked at 8 degrees and code P1689 (DME, electronic throttle monitoring error). The technician noted the vehicle had multiple VINs in different modules and suspected a misconfigured DME.

Other codes + test results:

- P0036 – O2 sensor heater control circuit (Bank 1 Sensor 2)

- P0130 – O2 sensor malfunction (Bank 1, Sensor 1)

- P0340 – Camshaft sensor malfunction

- P1689 – Throttle monitoring error (DME), torque calculation issue

- Fuel trims: ±10%

- TPS Sensor 1 & 2 readings: Close to 5 volts throughout the range

Other mechanics suggestions:

- Check wiring diagrams for common grounds, 5V reference, and shared wiring between affected items.

- Unplug O2 sensors, throttle body, and PCM to test circuits, ensuring they can carry enough current using a test bulb.

- Clear all module memories and drive the vehicle again, focusing on engine mechanicals, timing, power, grounds, charging systems, and wiring harnesses.

Final fix:

The issue was traced to the cluster module (KOMBI), which had a different VIN than the other modules. The customer declined the repair, and the vehicle was not fully fixed.

Case #10: Audi

Vehicle information: 2004 Audi Allroad Quattro 2.7L

Issue + repair history:

The MIL (Malfunction Indicator Lamp) is on, and the vehicle keeps resetting heater performance and warmup codes for both pre-cat and post-cat oxygen sensors. The pre-cat O2 sensor has been observed to have a slow warmup. Both post-cat sensors were replaced with OE parts, but the issue persists. The technician suspects that the ECM or wiring could be the cause but hasn’t confirmed it yet.

Other codes + test results:

- P0036 – HO2S heater circuit (Bank 1, Sensor 2)

- P0141 – HO2S heater circuit (Bank 1, Sensor 2)

Other mechanics suggestions:

- Check power and ground to the O2 sensor heater, as it may be controlled by the ECM.

- Inspect the power supply from the fuel pump relay, which powers both the fuel pump and the O2 sensor heaters in some Audi models.

- Load test the wiring with a 12-volt headlight or similar to see if the circuit can handle the current. Bad grounds can show voltage on a meter but fail under load.

- Swap the rear O2 sensors to see if the problem follows the sensor, which could rule out the sensor itself.

- Some suggested that the ECM may be faulty or there might be a reflash available to correct the issue.

Final fix:

After swapping the rear O2 sensors and confirming that the code did not follow the sensor, the technician concluded that the issue was likely with the ECM or wiring. The car was sent to another shop, where the rear O2 sensor was replaced again, but the code returned. The customer was advised that the ECM or its connector likely needed replacement to resolve the issue.

Test oxygen sensor PDF

- How to locate a specific sensor (bank1, 2)

- How to test with a multimeter

- How to test using an OBD-II reader

- Verify O2 sensor/CAT just with live data

Hi, I am Juraj “Yuri” Lukacko. I got frustrated by unhelpful and scammy mechanics, so I decided to learn everything about car diagnostics myself. I test dozens of new car diagnostic tools every month along with learning new strategies to fix and customize cars. About Juraj Lukacko (Yuri)