The P0041 code indicates a problem with the oxygen (O2) sensor signals being swapped between Bank 1 and Bank 2 Sensor 2. This issue can lead to rough idling, decreased fuel efficiency, reduced engine performance, and occasional stalling. Fixing this issue involves inspecting and potentially replacing the O2 sensors, along with checking for any related wiring or system faults.

P0041 quick overview

| Meaning | P0041 – O2 Sensor Signals Swapped Bank 1 Bank 2 Sensor 2 |

| Is it serious? | Yes, it can lead to significant engine performance issues and impact fuel economy. |

| Possible causes | – Faulty O2 sensor – Damaged wiring or connectors – Vacuum leaks in the intake system – Exhaust system leaks |

| How to diagnose? | Inspect wiring and connectors for damage or corrosion. Swap the O2 sensors between banks to see if the issue follows the sensor. Check for vacuum leaks in the intake system. Inspect the exhaust system for leaks affecting O2 sensor readings. |

Case Study: Fixing P0041 on 7 different cars

I looked into P0041 service cases at iatn.com website where in the private forums the mechanics seek advice from other mechanics. I looked up a bunch of cases to help you decide how to fix your issue and see what would a real mechanic do to solve it.

Common fixes

| Fix | Percentage |

|---|---|

| Repair or replace damaged O2 sensor wiring | 40% |

| Correct swapped O2 sensor connections | 35% |

| Replace faulty O2 sensors | 20% |

| Other | 5% |

Common mistakes

- Overlooking swapped O2 sensor connections between Bank 1 and Bank 2, which can lead to incorrect data readings.

- Not thoroughly inspecting wiring harnesses and connectors for damage or corrosion, resulting in recurring issues.

- Focusing on replacing parts like O2 sensors without first verifying the integrity of connections and wiring.

- Ignoring the need for live data analysis using a diagnostic tool to verify correct O2 sensor operation before replacing components.

Key takeaway

- Always double-check the O2 sensor connections to ensure they are correctly installed in their respective banks before replacing sensors.

- Use diagnostic tools to monitor live O2 sensor data, ensuring that readings correspond to the correct bank and sensor.

- Inspect wiring and connectors carefully for damage, as even minor issues can lead to persistent errors like P0041.

- Verify exhaust system integrity, including checking for leaks, as they can impact O2 sensor readings and contribute to this code.

- Address additional underlying issues like lean conditions or misfires, as they may cause or be influenced by O2 sensor-related problems.

Case #1: Ford P0041

Vehicle information

Ford F-150 V8 2017

Issue + repair history

- Owner reported check engine light illuminated.

- Previous repairs: None mentioned.

- Current symptoms: Check engine light on, rough idling, decreased fuel efficiency.

Other OBD2 Codes + Test Results

- P0041: O2 Sensor Signals Swapped Bank 1 Bank 2 Sensor 2

- P0174: System Too Lean (Bank 2)

- Live data: O2 sensor readings from Bank 1 and Bank 2 swapped.

Mechanic suggestions

- Inspect the wiring harness and connectors for any signs of damage or corrosion.

- Swap the O2 sensors from Bank 1 and Bank 2 to verify if the problem follows the sensor.

- Check for any vacuum leaks in the intake system that could cause a lean condition.

Final fix

Replaced faulty O2 sensor on Bank 2, Sensor 2, and cleared error codes.

Case #2: Toyota P0041

Vehicle information

Toyota Tacoma V6 2019

Issue + repair history

- Owner noticed reduced engine performance and occasional stalling.

- Previous repairs: None mentioned.

- Current symptoms: Check engine light on, rough idling, hesitation during acceleration.

Other OBD2 Codes + Test Results

- P0041: O2 Sensor Signals Swapped Bank 1 Bank 2 Sensor 2

- P0300: Random/Multiple Cylinder Misfire Detected

- Live data: O2 sensor readings from Bank 1 and Bank 2 swapped.

Mechanic suggestions

- Check the wiring connections at the O2 sensors for any issues.

- Inspect the ignition system for any faults, including spark plugs and ignition coils.

- Test the fuel pressure to ensure it is within the manufacturer’s specifications.

Final fix

Repaired damaged wiring at the O2 sensor connector on Bank 1, Sensor 2, and cleared error codes.

Case #3: Chevrolet P0041

Vehicle information

Chevrolet Silverado V8 2020

Issue + repair history

- Owner complained of engine hesitation and reduced power.

- Previous repairs: None mentioned.

- Current symptoms: Check engine light on, reduced acceleration, engine hesitation.

Other OBD2 Codes + Test Results

- P0041: O2 Sensor Signals Swapped Bank 1 Bank 2 Sensor 2

- P0306: Cylinder 6 Misfire Detected

- Live data: O2 sensor readings from Bank 1 and Bank 2 swapped.

Mechanic suggestions

- Inspect the wiring harness and connectors for any signs of damage or corrosion.

- Swap the O2 sensors from Bank 1 and Bank 2 to verify if the problem follows the sensor.

- Check for any exhaust leaks or issues that could affect O2 sensor readings.

Final fix

Replaced faulty O2 sensor on Bank 1, Sensor 2, and cleared error codes.

Case #4: Chevrolet

Vehicle information: 2001 Chevrolet Impala 3.4L

Issue + repair history:

The vehicle was brought in for an emission inspection with the check engine light on and code P0141, indicating a malfunction in the oxygen sensor heater circuit for Bank 1, Sensor 2 (B1-S2). The rear O2 sensor was replaced, and the code was cleared. However, after three days, some monitors, including the O2 heater, had not reset, and the P0141 code reappeared in the pending status without illuminating the MIL. Power was confirmed at the O2 sensor’s pink wire (12.6 volts), and ground was good, but no voltage was detected on the tan and purple wires, which correspond to O2 sensor high and low. The tan wire appeared inactive, while the purple wire showed resistance to ground.

Other codes + test results:

Other mechanics’ suggestions:

- Verify continuity between the O2 sensor and PCM; if continuity is intact, the issue may lie within the PCM.

- Use only OEM (Delco) O2 sensors, as aftermarket sensors can sometimes cause issues.

- Ensure two proper drive cycles are completed to reset the O2 monitor.

- Consider inspecting the wiring harness for damage, especially near areas with protective shields where dirt and debris can cause wire wear.

Final fix:

The problem was traced to a defective PCM. Replacing the PCM resolved the issue, and the O2 sensor heater circuit functioned correctly, allowing the monitors to reset and the vehicle to pass the emission inspection.

Case #5: BMW

Vehicle information: 2003 BMW 325i 2.5L

Issue + repair history:

The vehicle presented with a persistent MIL (Malfunction Indicator Lamp) and several recurring codes, including one for the O2 sensors indicating they were swapped and secondary air injection system codes. A previous repair involved replacing the MAF sensor, which temporarily resolved some issues, but the O2 sensor code remained. The connectors for the O2 sensors were checked and swapped, but the same code persisted. Additionally, the vehicle has had secondary air system codes since 48,000 miles, yet all tests for this system passed without any clear issues.

Other codes + test results:

- P0041: O2 Sensors Swapped, Bank 1 Sensor 2 and Bank 2 Sensor 2 (equivalent to BMW code 296B)

- P0412: Secondary Air Injection System Valve A Circuit (equivalent to BMW code 2761)

- P2098: Post Catalyst Fuel Trim System Too Lean, Bank 2 (equivalent to BMW code 28F3)

- P2273: O2 Sensor Signal Stuck Rich, Bank 2 Sensor 2 (equivalent to BMW code 28C6)

- P2096: Post Catalyst Fuel Trim System Too Lean, Bank 1 (equivalent to BMW code 28F2)

- P2271: O2 Sensor Signal Stuck Rich, Bank 1 Sensor 2 (equivalent to BMW code 28C5)

- Secondary air system tests – all passed

Other mechanics’ suggestions:

- Inspect vent hoses for leaks, which could cause the system to misinterpret lean conditions and adjust mixture incorrectly.

- Verify if the engine is an M56, as this may be covered under a dealer warranty.

- Double-check that the pre-cat O2 sensors are properly installed, as swapped sensors can lead to incorrect data and codes.

- Examine the air injection system’s check valve for exhaust backflow, which can damage the air pump.

- Test continuity between the O2 sensor connectors and the ECU to ensure the wiring is correctly routed, as the issue may reside in the harness rather than the sensors themselves.

Final fix:

The customer chose not to proceed with further repairs, opting instead to ignore the warning light by covering it with tape. The root cause of the issue was not definitively identified, but further testing and verification of the sensor wiring harness, air injection system, and vent hoses were recommended.

Case #6: GM

Vehicle information: 2003 Saturn Vue 3.0L

Issue + repair history:

The vehicle arrived with several codes, including P0300 (random misfire), P0301 (cylinder 1 misfire), P0421 (catalyst efficiency below threshold, Bank 1), and P2B03 (no information found). The technician monitored the O2 sensors and found that the downstream O2 sensor was mimicking the upstream sensor, indicating a likely issue with the catalytic converter. The spark plugs were replaced, and the Bank 1 coil assembly was changed due to rust intrusion around cylinder 1. The vehicle ran well on flat roads and uphill but exhibited rough running and misfire codes after a long downhill deceleration. The issue would resolve temporarily after restarting the vehicle.

Other codes + test results:

- P0300: Random misfire

- P0301: Cylinder 1 misfire

- P0421: Catalyst efficiency below threshold, Bank 1

- P0041: O2 sensors swapped (No info provided)

- P2B03: No information available

- O2 sensor readings during deceleration: 0 mV; during uphill driving: 750-900 mV; at idle: normal switching between rich and lean

Other mechanics’ suggestions:

- Check fuel pressure during the rough running condition to rule out a fuel delivery issue.

- Monitor scan data for O2 sensors, MAP sensor readings, and injector pulse width during the problem.

- Perform a backpressure test to check for a plugged exhaust system or use a vacuum gauge to detect a restriction.

- Inspect for a faulty throttle position during deceleration, which might cause incorrect fuel cut behavior.

- Consider replacing the catalytic converter since the O2 sensor readings suggest it may be faulty.

Final fix:

The catalytic converter was replaced, which resolved the misfire and rough running issue. The vehicle no longer exhibited problems after a long downhill deceleration, and the codes did not return.

Case #7: BMW

Vehicle information: 2007 BMW 328xi 3.0L

Issue + repair history:

The vehicle arrived with a non-running condition and a dead battery, with the key stuck in the dash. After jump-starting, it barely ran and required a new alternator due to oil contamination from a leaking oil filter cap. A new alternator, cap, and seal were installed, along with a serpentine belt. The car initially ran rough but would occasionally smooth out, leading to a test drive where it lost power after 4 miles, setting misfire codes for cylinders 3, 4, 5, and 6. Further investigation revealed melted catalytic converters, which were replaced, along with all spark plugs and coils. The vehicle continued to misfire, particularly on cylinder 6, under specific conditions like quick throttle releases or during hard acceleration. Various tests, including checking crankcase vacuum and fuel pressure, were performed without identifying the root cause.

Other codes + test results:

- P0306: Misfire Cylinder #6

- P0304: Misfire Cylinder #4

- Fuel adaptations: +12.38 and +13.25

- Fuel pressure: 61 psi with key on, 71 psi engine running, fluctuating during misfire

- Compression test: 175-180 psi across all cylinders

- MAF readings: 11.4 kg/h at idle, 31-33 kg/h at 2000 rpm

Other mechanics’ suggestions:

- Inspect fuel injectors for potential leakage or malfunction, which can cause misfires.

- Check the PCV system and related vacuum hoses for any faults or blockages.

- Measure crankcase vacuum levels using a manometer or gauge; excessive vacuum could indicate a PCV issue.

- Verify the proper function and connection of O2 sensors, ensuring they are not swapped.

- Examine the Valvetronic system for issues with the adjustment or malfunctioning components.

- Use an emission analyzer to check for possible head gasket leaks by sniffing for hydrocarbons in the coolant.

Final fix:

The issue was resolved by correcting swapped rear O2 sensor connections, which occurred during the catalytic converter replacement. The swapped sensors led to incorrect readings and misfire codes. After properly connecting the sensors and adding fresh fuel, the vehicle ran smoothly with no further misfires. The problem was identified after rechecking the O2 sensor connections during a scan, which revealed a new code related to the swapped sensors.

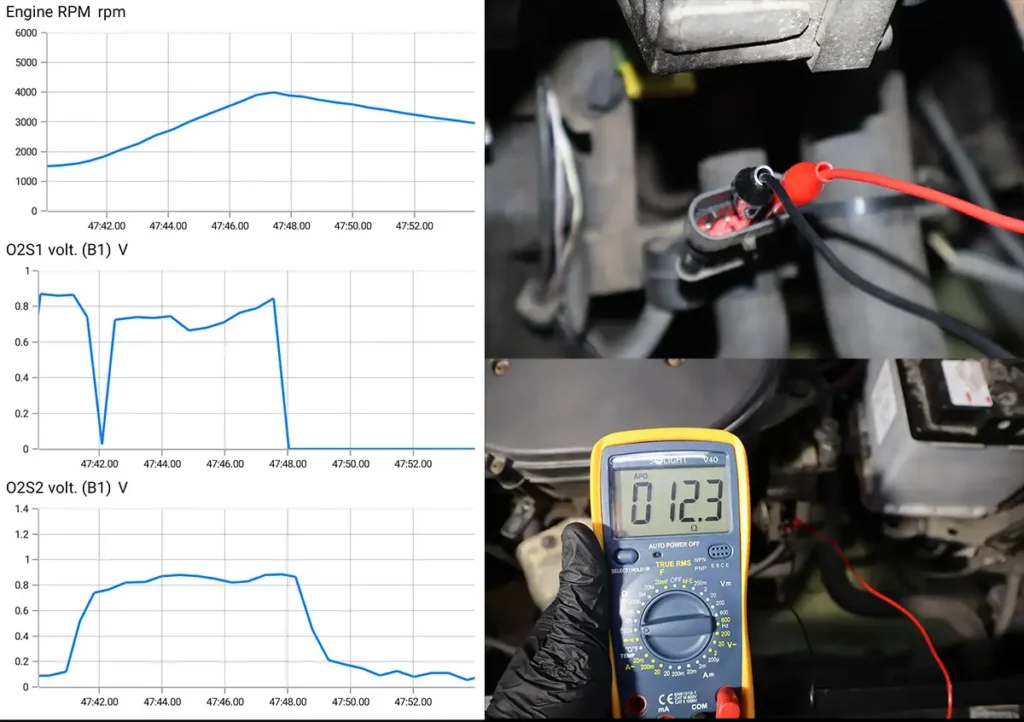

Test oxygen sensor PDF

- How to locate a specific sensor (bank1, 2)

- How to test with a multimeter

- How to test using an OBD-II reader

- Verify O2 sensor/CAT just with live data

I test OBD-II scanners and make DIY Engine diagnostics guides to help you solve your car problems without having to depend on the mechanic. A lot of them will try to scam you or are just no help at all. About Juraj Lukacko