The P0040 code signals an issue where the oxygen (O2) sensor signals for Bank 1 and Bank 2, Sensor 1, are swapped. This can lead to poor engine performance, rough idling, decreased fuel efficiency, and engine misfires. Addressing this involves checking the O2 sensors, their wiring, and possibly the exhaust and intake systems to correct the swapped signals and restore engine efficiency.

P0040 quick overview

| Meaning | P0040 – O2 Sensor Signals Swapped Bank 1 Bank 2 Sensor 1 |

| Is it serious? | Yes, it can cause significant engine performance issues and impact fuel efficiency. |

| Possible causes | – Faulty O2 sensor – Damaged wiring or connectors – Exhaust system leaks – Problems in the intake system |

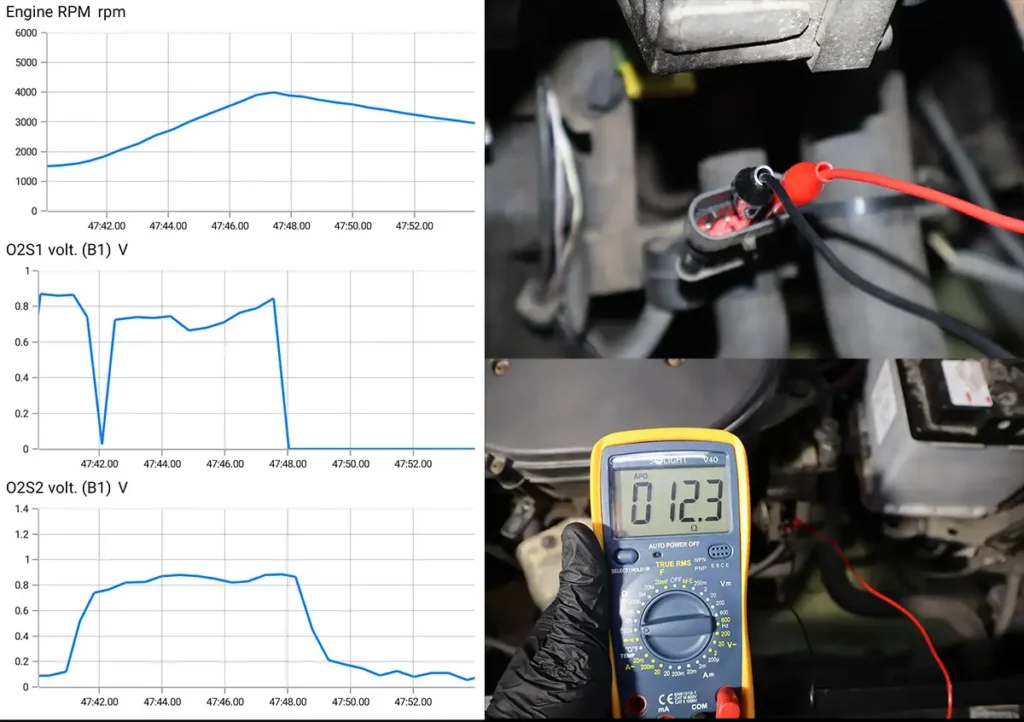

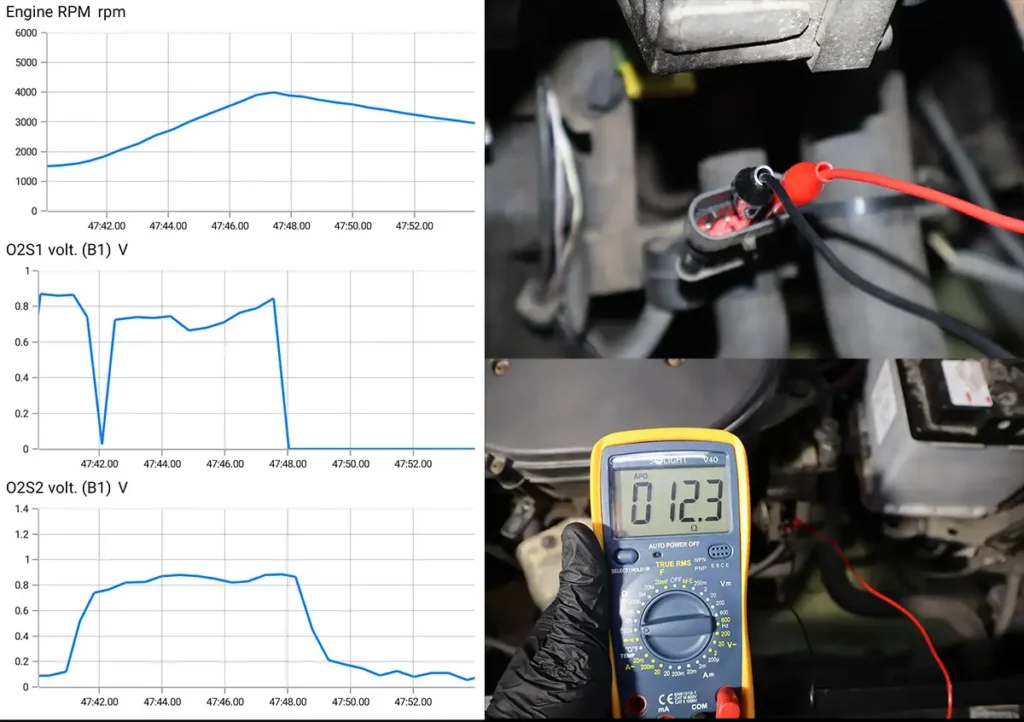

| How to diagnose? | Inspect wiring and connectors for damage or corrosion. Swap the O2 sensors between banks to see if the issue follows the sensor. Check the exhaust system for leaks that could affect sensor readings. Verify the intake system for any leaks or vacuum hose damage. |

Test oxygen sensor PDF

- How to locate a specific sensor (bank1, 2)

- How to test with a multimeter

- How to test using an OBD-II reader

- Verify O2 sensor/CAT just with live data

Case study: Fixing P0040 on 6 vehicles

I looked into P0040 service cases at iatn.com website where in the private forums the mechanics seek advice from other mechanics. I looked up a bunch of cases to help you decide how to fix your issue and see what would a real mechanic do to solve it.

Common fixes

| Fix | Percentage |

|---|---|

| Repair or replace damaged O2 sensor wiring | 40% |

| Replace faulty O2 sensor | 35% |

| Correct swapped O2 sensor connections | 25% |

| Other | 5% |

Common mistakes

- Not verifying the correct connections between O2 sensors on Bank 1 and Bank 2 before replacing parts.

- Failing to inspect and repair damaged or corroded wiring and connectors at the O2 sensors.

- Overlooking the need to use diagnostic tools to check live data, which can help identify swapped sensor signals.

- Replacing O2 sensors without addressing underlying issues like exhaust leaks or faulty wiring, leading to recurring issues.

Key takeaway

- Always verify that O2 sensors are correctly connected to their respective banks before proceeding with repairs.

- Use diagnostic tools to monitor live O2 sensor data, ensuring that readings correspond to the correct sensors.

- Thoroughly inspect wiring and connectors for any damage, corrosion, or signs of wear, as these can often cause P0040 codes.

- When replacing O2 sensors, ensure they are properly installed and positioned to avoid mismatched signals between banks.

- Address any additional engine performance issues, like vacuum leaks or misfires, as these can affect O2 sensor readings and lead to persistent errors.

Case #1: Ford P0040

Vehicle information

Ford Mustang GT V8 2018

Issue + repair history

- Owner complained of poor engine performance and rough idling.

- Previous repairs: Replaced spark plugs and ignition coils.

- Current symptoms: Check engine light on, engine misfires, reduced power output.

Other OBD2 Codes + Test Results

- P0040: O2 Sensor Signals Swapped Bank 1 Bank 2 Sensor 1

- P0300: Random/Multiple Cylinder Misfire Detected

- Live data: O2 sensor readings from Bank 1 and Bank 2 swapped.

Mechanic suggestions

- Check the wiring harness and connectors for any signs of damage or corrosion.

- Swap the O2 sensors from Bank 1 and Bank 2 to verify if the problem follows the sensor.

- Inspect the exhaust system for any leaks or issues that could affect O2 sensor readings.

Final fix

Replaced faulty O2 sensor on Bank 2, Sensor 1, and cleared error codes.

Case #2: Toyota P0040

Vehicle information

Toyota Camry V6 2019

Issue + repair history

- Owner noticed a decrease in fuel efficiency and occasional stalling.

- Previous repairs: None mentioned.

- Current symptoms: Check engine light on, rough idling, hesitation during acceleration.

Other OBD2 Codes + Test Results

- P0040: O2 Sensor Signals Swapped Bank 1 Bank 2 Sensor 1

- P0171: System Too Lean (Bank 1)

- Live data: O2 sensor readings from Bank 1 and Bank 2 swapped.

Mechanic suggestions

- Check the wiring connections at the O2 sensors for any issues.

- Verify the integrity of the intake system for any leaks or vacuum hose damage.

- Test the fuel pressure to ensure it is within the manufacturer’s specifications.

Final fix

Repaired damaged wiring at the O2 sensor connector on Bank 1, Sensor 1, and cleared error codes.

Case #3: Chevrolet P0040

Vehicle information

Chevrolet Silverado V8 2020

Issue + repair history

- Owner reported a decrease in engine power and occasional rough idling.

- Previous repairs: Replaced the mass airflow sensor.

- Current symptoms: Check engine light on, reduced acceleration, engine hesitation.

Other OBD2 Codes + Test Results

- P0040: O2 Sensor Signals Swapped Bank 1 Bank 2 Sensor 1

- P0306: Cylinder 6 Misfire Detected

- Live data: O2 sensor readings from Bank 1 and Bank 2 swapped.

Mechanic suggestions

- Inspect the wiring harness and connectors for any signs of damage or corrosion.

- Swap the O2 sensors from Bank 1 and Bank 2 to verify if the problem follows the sensor.

- Check for any exhaust leaks or issues that could affect O2 sensor readings.

Final fix

Replaced faulty O2 sensor on Bank 1, Sensor 1, and cleared error codes.

Case #4: Oldsmobile

Vehicle information: 1998 Oldsmobile Intrigue 3.8L

Issue + repair history:

The car came in with a P0040 code indicating a problem with a wheel sensor. The technician found a dead right front (R/F) wheel sensor, replaced it, and also replaced the front pads and rotors. After the repair, the P0040 code reappeared during sharp turns. The scanner showed that during sharp turns, one of the rear speed sensors would read about 8 mph slower than the other three sensors, while in normal driving or shallow turns, all sensors read correctly.

Other codes + test results:

No additional codes were provided.

Other mechanics’ suggestions:

- Verify the condition of the harness and connector at the wheel speed sensor; twisted wires near a flex point can cause intermittent issues.

- Check for loose or corroded connections at the speed sensor and debris in the tone ring.

- Consider using an OE hub bearing/sensor as some aftermarket units may have reliability issues.

- Inspect for a “rub through” issue at the sensor wiring harness, especially at areas prone to flexing.

Final fix:

The technician found a nearly broken wire about 12 inches back into the harness. Replacing the pigtail resolved the issue, eliminating the code and restoring proper speed sensor function during turns.

Case #5: Land Rover

Vehicle information: 2005 Land Rover Range Rover HSE 4.4L

Issue + repair history:

After head gasket, cam chain, and cam chain tensioner replacements, the vehicle initially ran smoothly with good fuel trims. However, after approximately 150 miles, the customer returned with misfires on all cylinders in Bank 2, and the vehicle had a rough idle but smoothed out above 1500 RPM. A code P0040 (B1S1 O2 sensor swapped with B2S1 O2) appeared immediately after clearing codes. A compression test showed low compression in cylinders #5 and #6 (75 psi), which improved with oil added, suggesting possible ring issues. The B1 intake cam appeared to have more resistance than the B2 cam, indicating potential VANOS issues.

Other codes + test results:

- P0305: Misfire cylinder 5

- P0306: Misfire cylinder 6

- P0307: Misfire cylinder 7

- P0308: Misfire cylinder 8

- P0040: B1S1 O2 Sensor swapped with B2S1 O2

- Compression test: Cylinders #5 & #6 at 75 psi, improved to 100 psi with oil added

- Smoked tested – good, no leaks detected

Other mechanics’ suggestions:

- Inspect for weak valve springs, sticking valves, or valve seat issues

- Perform a leak-down test to determine the source of compression loss

- Check cam timing using crankshaft gear adaptation values on the scan tool

- Verify condition of the catalytic converters for potential blockage

- Consider the possibility of the cam sensor wheel being out of time relative to the camshaft

Final fix:

The issue was resolved by replacing the Bank 2 VANOS actuator and both VANOS solenoids, which were leaking oil into the ECU connectors. This fixed the timing variation between the banks when running, leading to restored compression and smooth idle. After driving 130 miles post-repair, the fuel trims were stable within +/- 3%, and no further misfire codes or O2 sensor errors returned.

Case #6: Mercedes-Benz

Vehicle information: 2006 Mercedes-Benz C280 4Matic 3.0L

Issue + repair history:

The vehicle suddenly developed a misfire, and the MIL came on. Misfires were detected on cylinders 1, 4, and 6. The right bank spark plugs (cylinders 1, 2, 3) appeared very black, indicating a rich condition, while the left bank plugs (cylinders 4, 5, 6) looked normal. A smoke test revealed no vacuum leaks. O2 sensor readings were unusual, with the right bank upstream sensor showing 20 volts, far outside the expected 0-1 volt range. The technician initially planned to replace the O2 sensor and all six spark plugs.

Other codes + test results:

- P0300: Random Misfire

- P0301, P0304, P0306: Misfires on Cylinders 1, 4, and 6

- P2626: Right upstream O2 sensor open

- P0040: O2 upstream connector mismatch

- P2A00: O2 right upstream shifted to lean

- P2414: O2 right upstream signal implausible

Other mechanics’ suggestions:

- Confirm if the car has wideband O2 sensors, which read different voltages.

- Check for a clogged catalytic converter by loosening the exhaust flange to see if performance improves.

- Verify if oil contamination is present in the harness, especially around the VVT solenoids and DME connectors.

- Use a direct scope or multimeter on the O2 sensor to verify readings.

Final fix:

After considering the unusual O2 readings and potential causes, the catalytic converter was suspected to be blocked. The vehicle was towed to a dealership, where they replaced the right upstream O2 sensor. The replacement resolved the misfires and rich condition on the right bank. Subsequent temperature readings of the catalytic converters showed the right side running hotter, indicating it had been working harder due to the rich mixture. With the new O2 sensor, the vehicle ran smoothly, though the customer had to pay for both independent diagnostic time and the dealership repair.

Test oxygen sensor PDF

- How to locate a specific sensor (bank1, 2)

- How to test with a multimeter

- How to test using an OBD-II reader

- Verify O2 sensor/CAT just with live data

I test OBD-II scanners and make DIY Engine diagnostics guides to help you solve your car problems without having to depend on the mechanic. A lot of them will try to scam you or are just no help at all. About Juraj Lukacko